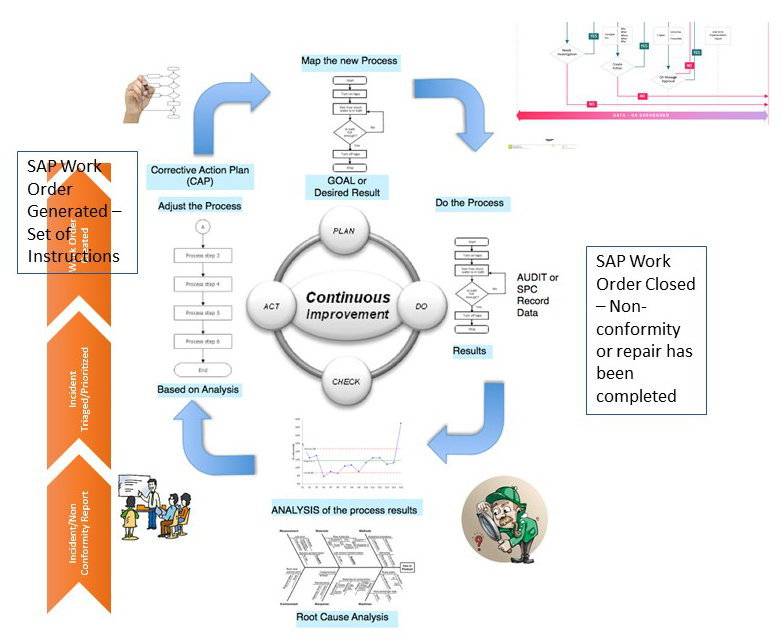

People do not follow procedures because sometimes they don’t even know that procedures exist, or those procedures are not updated/revised after events.įDA - Corrective and Preventive Actions (CAPA)įDA - Form 483 Observations and Warning Letters However, people should view CAPA’s as an opportunity to improve a product and prevent problems in the future. They focus on the words, but do not try to understand the meaning.ĬAPAs often generate negative connotations-the process requires extra work and more resources, not in the budget, and time pressure. When something happens unexpectedly, will it happen again? What are you changing to ensure it does not happen again?ĬAPAs continue be the #1 reason because people do not have a common sense understanding of the quality system regulation. Processes and routines may not go routinely. Things happen every day during the course of running a business. If CAPA is the #1 reason why companies are getting 483 observations and warning letters, it may be due to an ineffective quality management system (QMS). The five most common reasons why the FDA issued 483 observations and warning letters over the last 5 years were CAPAs, customer complaints, purchasing controls, medical device reporting, and process validation. People tend to report every little event as a CAPA or report nothing at all. Only 3-5% of adverse events of medical devices are actually reported to the manufacturer or FDA. Like this episode? Subscribe today on iTunes or Spotify. Why are medical devices companies continuing to struggle with CAPAs? Listen now: In this episode of the Global Medical Device Podcast, Jon Speer talks to Mike Drues of Vascular Sciences about whether your medical device company’s CAPA process needs a CAPA. Have you done Corrective and Preventive Actions (CAPA) on your CAPA process? If not, you need to seriously consider doing so because CAPA is the #1 reason why companies get 483 observations year after year.

0 kommentar(er)

0 kommentar(er)